5/16" Flooring

5/16" Square Edge Strips

Lebanon Oak’s fine selection of Red or White Oak, available in most grades, with that special square edge cut.

Dimension & Species

- 5/16" x 2" - Select and Better Red Oak

- 5/16" x 2" - #1 Common Red Oak

- 5/16" x 2" - #2 Common Red Oak

- 5/16" x 2" - Select and Better White Oak

- 5/16" x 2" - #1 Common White Oak

- 5/16" x 1", 1 1/2", & 1 1/3" - Select and Better Red Oak

- 5/16" x 1", 1 1/2", & 1 1/3" - Select and Better White Oak

Instructions

- Cut: Square edge; unfinished strips; lengths range from 2'-14'.

- Installation: Flooring is installed by face nailing or with proper adhesive.

- Weight: 1200 lbs. per M square foot.

- Feature Strips: Available in Walnut, Cherry, Maple and Hickory.

Select & Better Plank

The natural color of Red or White Oak comes alive in Lebanon Oak’s, Select and Better grades. The deep, rich wood grains give variety to all types of wood floors.

Dimension & Species

- 5/16" x 3" - 4"- 5" - 6" - 7"- 8"; Red Oak

- 5/16" x 3" - 4" - 5" - 6" - 7"- 8"; White Oak

Instructions

- Cut: Bevel or square edge.

- Installation: Flooring is installed by face nailing with or without plugs or with proper adhesive.

- Shipping: Lengths range from 2' - 12'.

- Weight: 1200 lbs. per M square foot.

Select & Better Plank - Beveled Edge

Lebanon Oak, LLC brings you beautiful Red and white Oak chosen from the heart of Kentucky’s outstanding timberland.

Dimension & Species

- 5/16" x 3" - 5" - 7"

Instructions

- Cut: Bevel edge; unfinished; random plank.

- Installation: Flooring is installed by face nailing with or without plugs or with proper adhesive.

- Shipping: Each width of flooring is shipped approximate equal board footage or equal lineal footage. Lengths range from 2' - 12'.

- Species: Red Oak only.

- Weight: 1200 lbs. per M square foot.

Parquetry Flooring

Lebanon Oak, LLC offers its Red and White Oak grades for use in Parquetry Block Flooring. Available on special orders only.

Dimension & Species

- 5/16" x 12" x12"; available in 2", 1 1/3" or 1 1/2" slats.

Instructions

- Description: Unfinished, square edge.

- Installation: Flooring is installed by adhesive or face nailing.

- Species: Clear Red Oak, Select Red Oak, Special Red Oak, Common Red Oak, Select and Better White Oak, Special White Oak, and Common White Oak.

- Weight: 1200 lbs. per M square foot.

Herringbone Flooring

For the special effect of patterned flooring, Lebanon Oak, LLC presents its Red and White Oak grades.

Dimension & Species

- 5/16" x 2" x specified length.

- 1/2" x 1 1/2" - 2" - 3"

- 3/4" x 1 1/2" & 2 1/4" & 3 1/4" & 4" & 5"

Instructions

- Description: Unfinished slats for pattern purposes.

- Species: Red or White Oak available in Select and Better grades.

- Installation: Flooring is installed by adhesive or face nailing.

- Weight: 5/16" - 1200 lbs. per M square foot.

- 1/2" - 1540 lbs. - Red Oak

- 1/2" - 1690 lbs. - White Oak

- 3/4" - 2530 lbs. - Red Oak

- 3/4" - 2700 lbs. - White Oak

Installation Instructions

Installing NOFMA-Certified Solid Wood Flooring Directly to a Slab Using a Wood Flooring Adhesive

The following recommendations and instructions apply to “on-grade” and “above-grade” slab construction. “Below grade” application of solid wood flooring is not recommended.

OVERVIEW:

Historically, NOFMA has not recommended glue-down application of wood flooring to a concrete slab. The basis for this position has been that NOFMA standards for wood flooring manufacture assume the flooring will be installed on wood-based subflooring systems with mechanical wood fasteners, nails, cleats, staples, etc. Today, building homes on concrete slabs is the normal construction technique in many areas of the country.

In recent years, advancements in adhesive technology and moisture retarders have made it possible to successfully glue solid wood flooring to concrete slabs in situations other than parquet applications. A concrete slab does not behave the same way as a traditional wood system, particularly concerning nailing. In addition, a slab can be a potential moisture source and adversely affect the performance of the flooring dramatically. As such, glue-down applications require the installer to take additional steps to ensure success. Still, some wood flooring manufacturers may not approve of direct glue down of their solid wood products. As such you should always follow the instructions and limitations published by the manufacturer. When in doubt, NOFMA recommends checking with the manufacturer before installation.

For more information, please see the technical information published on the NOFMA website regarding glue-down installation.

Installing NOFMA-Certified Solid Wood Flooring Using Traditional Nailing

“To install 5/16″ strip or plank you need a clean, dry flat wood sub-floor about 3/4″ – 7/8″ thick. 5/16″ x 2” oak strip can be laid with a 4 or 5 board border, if desired. The corners or offsets are either mitered or log cabined for desired effect. Some border incorporate “feature strips” of contrasting color; such as walnut, mahogany, redwood, teak, etc. These feature strips come in 5/16″, 1/2″ and 3/4″ widths and are used either one or two per border.

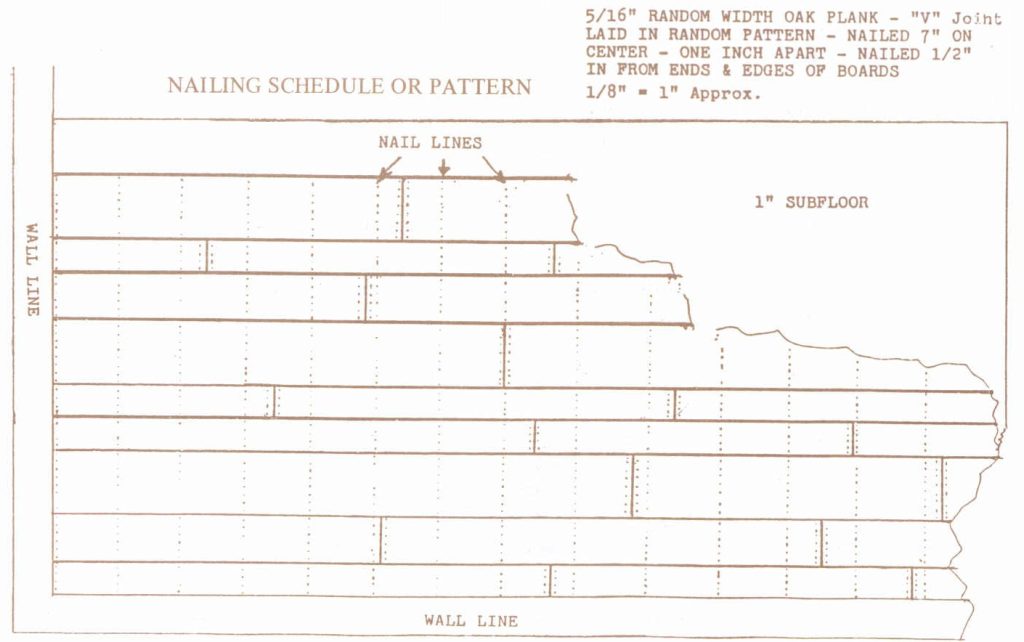

On occasion, patterns are built into the corners depending on the skill of the floor layer, and the designs detailed. The border should be squared to the room and any necessary rips scribed in at the wall line to take care of irregular runs in the wall line. The field is racked out loose, with the ends overlapping the positioned border. The flooring is then accumulated into a close or tight position by hand and then using any type of tool suitable for the purpose: i.e. a nail set, screw driver, chisel or like driver at a slight angle against the rack of loose boards, start a nail about a half inch in from the edge nearest you in the furthest board, apply tension with your took and while the rack is under tension, tack and set the nails. DON’T NAIL LOOSE BOARDS WITHOUT APPLYING TENSION; they can split. Accumulate and tack the whole floor into position and cut in rips as required. Strike chalk lines seven inches apart across the room and 1/2″ in from the edge of the boards. Butt joints are also nailed 1/2″ or 3/4″ in from the ends of the boards.

In the case of plank flooring, care should be taken in nailing the butts; to keep them out of the way of any plugs or dowels that may be desired in the floor. These floors are nailed with 1″ 15 gauge flooring brads, using our new Pneumatic Top Nailers, a Cavanaugh or equal nailer, making sure the boards are down to the subfloor and not up in the air. Floor should be trowel filled with wood filler. The filler seals floor and fills nail holes and any cracks. After filler has dried, sand and finish like any other wood floor.”

For more resources on general wood flooring information and for questions regarding installation, please visit the National Wood Flooring Association’s website.

Now Available

HighPro 5/16" Top Nailer

Mallet Operated For

- Downward force of the mallet holds the wood to the subfloor

- Nailing accuracy

- Ease of operation

- Prevention of squeaks

Base

- Has rolled corners for ease of sliding

- Is vividly marked on 4 sides for ease of alignment

- Is open for visibility and direction

Excellent For Countersinking Any Wood Thickness

Nails: 15 gauge, barbed shank, 1″ or 1 1/4″

Special Serrated Nails for Extra Holding Power!

Call to order or request information on this HighPRO item available through Lebanon Oak Flooring Co., LLC – (270) 692-2128

Now Available

Powernail 20-Gage Top Nailer

The industry’s first pneumatic, trigger-operated, 20-gage L-cleat top nailer. Uses the new 20-gage PowerCleats to insure less split-out on even the thinnest flooring.

Call to order or request information on this HighPRO item available through Lebanon Oak Flooring Co., LLC – (270) 692-2128

- Uses: 20 gage 1" and 1 1/4" PowerCleats

- Installs: 5/16" to 9/16" flooring

- Operating Pressure: 70-110 PSI

- Weight: 3lbs

Recommendations for Subfloors

Those areas of the country that use 5/16″ top nailed oak flooring should have at least 3/4″ of subfloor, or more ideally 7/8″ of subflooring. The nails used to fasten 5/16″ oak to the sub-floor are 1″ long. These nails are driven vertically and are countersunk into the top flooring. To contain the entire length of the nail and avoid splitting the subfloor or splintering it at the bottom; the overall thickness should be 1 1/8″ minimum, including the 5/16″ top floor. The 7/8″ subfloor would also add structural strength to the floor and avoid diaphragm or “diving board” action in the hundred of thousand of square feet of 5/16″ glued down parquets.

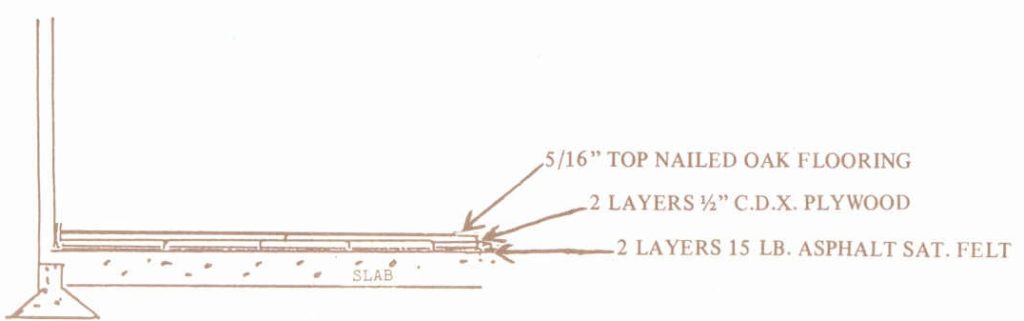

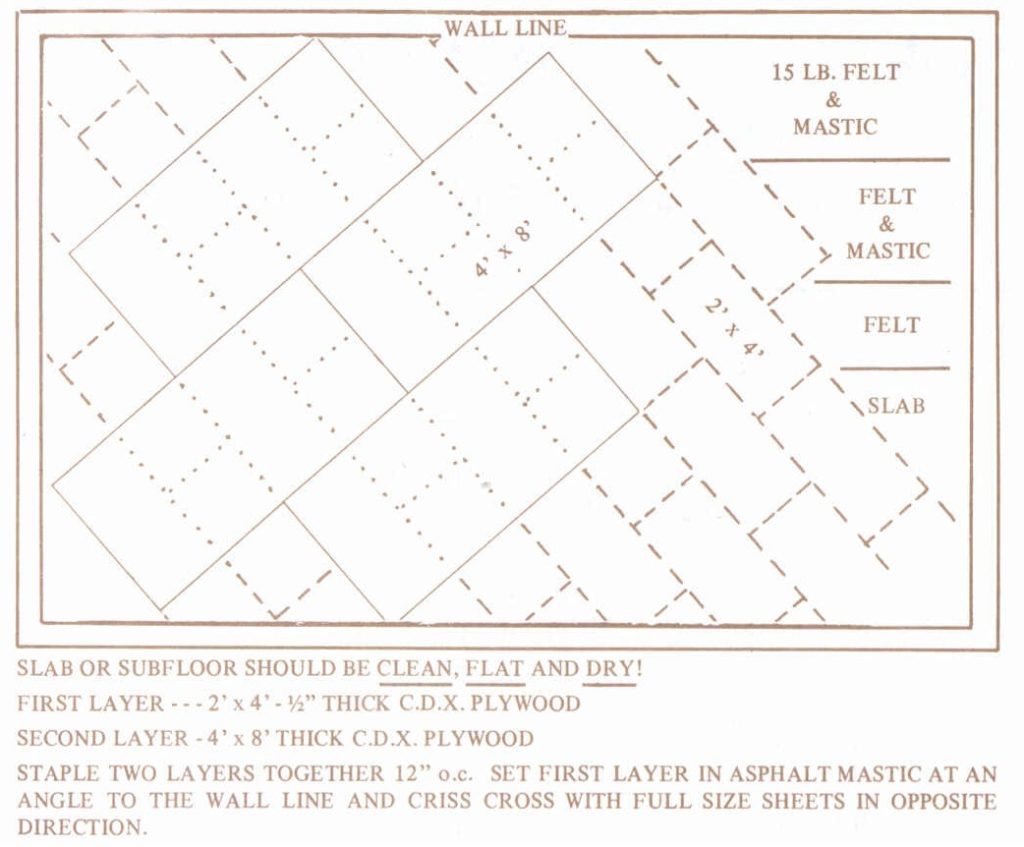

The method we suggest for "on-Grade" slabs & sometimes on suspended slabs is as follows:

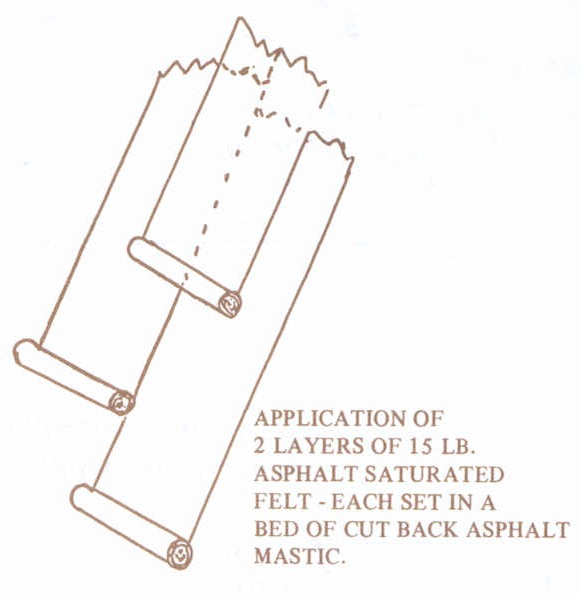

Two plies of 15-pound asphalt-saturated felt, each set in a bed of asphalt adhesive with the edges butted and the end joints offset and turned up the wall to the height of the finished floor. The second layer laps the first layer with a half sheet, to form a sealed vapor barrier.

Apply a third layer of asphalt adhesive using a 1/8″ notched trowel, over the membrane. Cut 1/2″ plywood, (not particle board) in 2′ x 4′ sheets; and install in the adhesive at a 45-degree angle to the wall line. Overlay the 2′ x 4′ pieces of plywood with full sheets of 1/2″ plywood, crisscrossing the first layer.

Staple the two layers of plywood together with 7/8″ divergent point stapes 12″ on center.

Before starting the job, the slab should be clean, flat, and dry.

This will provide a subfloor that will accept top nailed strip or plant, T & G strip of plank, and any glued down parquet and provide a strong, moisture resistant, versatile subfloor.

Fact Sheet

- A board foot of 5/16" flooring will lay a square foot of floor space. It is solid oak and has more wearing depth than 1/2" or 3/4" tongue and groove flooring.

- Once floor is laid, there is little visible difference between 5/16" flooring and T & G flooring. They are sanded and finished the same way. Different type of machines and nails are used to lay floor.

- Labor to lay-sand-finish 5/16" flooring is approximately the same as for T & G.

- Cost of 5/16" strip flooring is 15-25% less than T & G and is square edged.

- Cost of 5/16" plank flooring is 20-30% less than T & G in either beveled or square edged.

- The average length of 5/16" plank & strip flooring is 50 to 60% longer than other oak flooring. The appearance may be more pleasing as there are less pieces in floor.

- Also used as feature strips with other manufacturers 5/16" parquet flooring or cut to pickets to make smaller blocks appear as larger pattern type flooring or for other desired effects.

- 1000 bd. ft. of 5/16" x 2" equals 6000 Lineal ft. of feature strips.

- Since flooring is 5/16" of an inch thick, it is used to cover other floors, in remodeling work, laid over tile in entrance halls, over linoleum in kitchens & baths, in other rooms where wall to wall carpet is removed or over other type of floorings.

- The 5/16" plank is also used as borders for parquet floor and 3" plank is used as feature strip with blocks as in No. 9 above.

- The 5/16" plank is also used as wainscoting and wall paneling.

Disclaimer

Wood is a natural product, containing variations in color, decoration and grain. Before any flooring product leaves our plant, it goes through numerous inspections; as the installer of the flooring YOU are the final inspector. Allow five (5) per cent minimum for culling out (removing) undesirable pieces during the layout process. Some overwood/underwood and gaps are a natural occurrence in wood flooring. Small gaps can be filled with appropriate color match filler. All wood floor installations must follow NWFA (National Wood Flooring Association, www.nwfa.org) or NOFMA (National Oak Flooring Manufactures Association, www.nofma.org) guidelines. SOLID WOOD FLOORING MUST BE NAILED OR STAPLED OR GLUED DOWN OVER AN APPROPRIATE WOOD SUBFLOOR AS PER NWFA GUIDELINES.

All solid wood flooring requires acclimation time BEFORE it is installed. Check the moisture content (MC) of the flooring when it is delivered to the job site, and do not install until it reaches the desired MC for the climate and environment in which it is going to be used; adjusted to the species of wood being installed. For more information about the MC required in your area for the species of wood you are using call our technical department or contact the NWFA or NOFMA. Note: solid wood will not properly acclimate in wrappers/cartons, etc. Remove the flooring from its packaging, cross stack it on the job site and do not install until it is at the correct MC.

NOTE: WE ACCEPT NO RESPONSIBILITY OR LIABILITY FOR ANY MATERIAL ONCE IT HAS BEEN INSTALLED. IF THERE IS ANY QUESTION REGARDING FIT OR ANY OBVIOUS DEFECTS, DO NOT INSTALL! INSTALLATION ACKNOWLEDGES ACCEPTANCE OF THE MATERIAL.

THESE GENERAL INSTRUCTIONS ARE PROVIDED AS GUIDELINES ONLY. THE INSTALL/OWNER SHOULD REVIEW AND INSTALL ALL WOOD IN ACCORDANCE WITH THE STANDARDS SET BY THE NATIONAL WOOD FLOORING ASSOCIATION (NWFA) OR NATIONAL OAK FLOORING MANUFACTURES ASSOCIATION (NAFMA)

Hardwood flooring is a product of nature and therefore; not perfect. We start with all wood being manufactured in accordance with industry standards, which permit a defect tolerance not to exceed 5% determined within its grade. The defects may be of a manufacturing, finishing, milling or natural type.

Installer/Owner Responsibility

- It is the responsibility of the installer/owner to make final inspection of any product prior to installation. Carefully examine flooring for color, finish, milling and quality before installing. If flooring is not acceptable, in grade, color, milling or finish, do not install and contact the seller immediately. Flooring that is laid and later found or decided by installer/owner not to be what was ordered it will not be replaced or any monies reimbursed.

- Prior to installation of any hardwood flooring product, the installer/owner must determine that the job-site environment and the sub-surfaces involved meet or exceed all standards and recommendations of the construction and materials industries. The manufacturer declines any responsibility for job failure resulting from or associated with the sub-surface or job-site environment deficiencies.

- Should an individual piece be doubtful as to grade, color, manufacture or factory finish, the installer should not use the piece. If he does, seller's liability is limited to replace the defective material above the 5% allowable defect limit (not the labor cost involved).

- Use of stain, filler or putty stick for defect correction during installation should be accepted as normal procedure.

Job-Site Inspection

- Check the job-site before delivery. Be sure the flooring will not be exposed to excessive periods of high humidity or moisture. The surface grade or slope should direct water away from the building.

- Do not install below the outside soil line. Flooring should not be delivered until the building has been closed in and cement work, plastering, painting and other materials are complete and dry. Concrete and plaster should be 60-90 days old. Check all spaces under your home to be sure they are dry and well vented to avoid damage caused by moisture.

- Flooring should be at the job-site at least 72 hours prior to installation. This will allow flooring to acclimate to room conditions. If the job-site is unsatisfactory, have the flooring delivered and broken up into small lots and stored in the room where it is to be installed.

- The installation site should have consistent room temperature of 60-70 degree F for a minimum of 5 days prior and always after the installation of any hardwood flooring product.

Preparing Subfloor & Job-Site

- CLEAN-Sub floor must be scraped or sanded, broom cleaned, free of wax, grease, paint, oil and other debris. Subfloor must be smooth.

- PLYWOOD-Do not install over particle or chipboard. Subfloor should be constructed of 5/8" or thicker plywood (3/4" plywood is recommended). When installing directly over old wood or boards, sand any high spots, renail old floor to eliminate squeaks or loose boards.

- STRUCTURALLY SOUND-Nail or screw any loose areas that squeak. Replace any water damage subflooring or underlayment flooring product.

- DRY-Check moisture of subfloor. Moisture content of subfloor not to exceed more than 13% on a wood moisture meter. IF MOISTURE IS PRESENT CONTACT A PROFESSIONAL HARDWOOD FLOORING INSTALLER TO INSTALL A MOISTURE BARRIER SYSTEM. For homes without a basement, install a ground cover in a crawl space. Overlap plastic and tape seams. In a climate with extreme humidity or areas with excessive soil moisture, consider including expansion within the floor. This is done by using steel washers or putty knives as spacers.

3/4" & 1/2" T&G Flooring

3/4" Tongue And Groove

Tongue and Groove Flooring in 3/4″ thickness.

Dimension & Species

- 3/4" x 1 1/2" - 2 1/4" - 3 1/4" - Select & Better, Red and White Oak

- 3/4" x 1 1/2" - 2 1/4" - 3 1/4" - #1 Common Red and White Oak

- 3/4" x 1 1/2" - 2 1/4" - 3 1/4" - #2 Common Red and White Oak

Instructions

- Cut: Tongue and Groove. Unfinished

- Shipping: Lengths range from 1 1/4' - 10'.

- Species: Red and White Appalachian Oak

- Grade: Select & Better - #1 Common, #2 Common, lower grades accumulation only.

- Installation: Traditional blind nailing flooring installation

- Weight: 2.63 lbs / foot - red oak & 2.89 lbs / foot - white oak

1/2" Tongue And Groove

Tongue and Groove Flooring in 1/2″ thickness.

Dimension & Species

- 1/2" x 1 1/2" - Select & Better, Red and White Oak

- 1/2" x 1 1/2" - #1 Common Red and White Oak

- 1/2" x 1 1/2" - #2 Common Red and White Oak

- 1/2" x 2" - Select & Better, Red and White Oak

- 1/2" x 2" - #1 Common Red and White Oak

- 1/2" x 2" - #2 Common Red and White Oak

- 1/2" x 2 1/4" - Select & Better, Red and White Oak

- 1/2" x 2 1/4" - #1 Common Red and White Oak

- 1/2" x 2 1/4" - #2 Common Red and White Oak

- 1/2" x 3" - Select & Better, Red and White Oak

Instructions

- Cut: Tongue and Groove. Unfinished

- Shipping: Lengths range from 1 1/4' - 10'.

- Species: Red and White Appalachian Oak

- Grade: Select & Better - #1 Common, #2 Common, Rift/Qtr'd Accumulation only

- Installation: Traditional blind nailing flooring installation

- Weight: 1.72 lbs / foot - red oak & 1.93 lbs / foot - white oak

3/4" x 4" & 5" Tongue & Groove Plank Flooring

Plank Flooring

Plank Flooring

3/4" x 4" & 5" Tongue & Grove Plank Flooring

Dimension & Species

- Cut: Tongue and Groove. Unfinished

- Shipping: Lengths range from 2' - 11'.

- Species: Red & White Appalachian Oak

- Grade: Select & Better & Rustic

- Installation: Traditional blind nailing flooring installation and/or glue down application

- Weight: 2.63 lbs / foot - red oak & 2.89 lbs / foot - white oak